Suneast T3 Plus Screen Printer (520(X)×420(Y)—737(X)×737(Y) mm)

生産者: Suneast Model: T3 Plus - 連絡先

전화번호: いい価格のため、連絡しなさい

ホットライン: (+84) 968060220

電話番号: +84 (24)62923267

- Basic Parameters

Screen Frame Size: 520(X)×420(Y)—737(X)×737(Y) (mm); Thickness:20-40mm

Min PCB(mm): 50(X)×50(Y) (mm)

Max PCB(mm): 400(X)×310(Y) (mm)

Thickness: 0.2mm~6mm(Use jig when pcb less than 0.4mm)

Curve: <1%(Diagonal measurement)

PCB Backside Part Height: 10mm

Conveyor Height: 900±40mm

Support: Magnetic support, Magnetic piece, Vacuum chamber(Option)

Clamp: Side clamp(Standard),please read the to option table

Edge Distance: PCB process edge ≥2.5mm

Conveyor Speed: 0~1500mm/s,increment 1mm

Conveyor Belt: U type sync belt

Stopper method: Air Cylinder

Stopper position: Set the PCB stopper position according to the size of board

Flow direction: L-R、R-L、L-L、R-R depends on customer

- Print System

Print Speed: 5-200mm/s adjustable

Print Head: Step motor drive scraper lifting

Scraper: Steel scraper,rubber scraper(option)

Scraper Angle: 60°

Scraper Pressure: 0~20kg

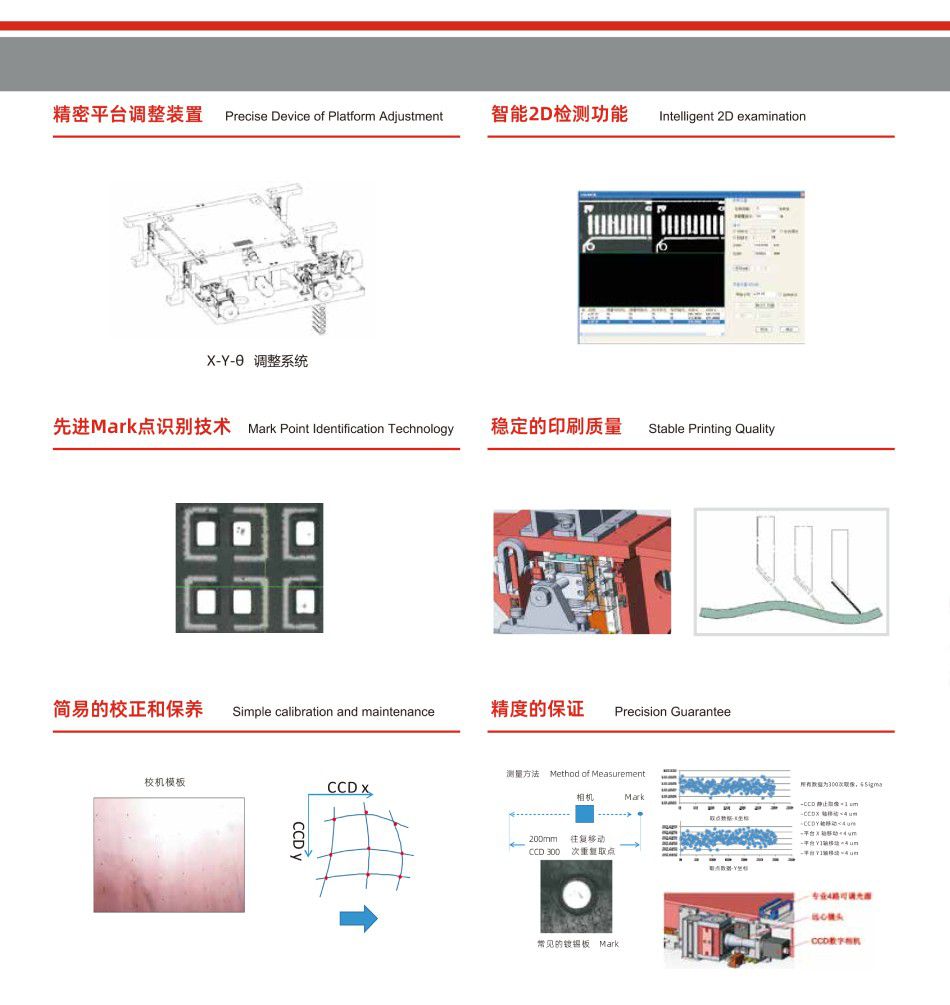

- Vision System

Substrate Separation: Three-section Substrate Separation speed:0.1-20mm/s distance:0-20mm

Alignment Position method: Mark automatic alignment

Camera: Germany BASLER,1/3” CCD,640*480pixel,pixel size:5.6μmx5.6μm

Acquire image method: Up/under double photo

Camera Light: Coaxial light,Ring light four kinds light can adjustable

View Range: 9mm*7mm

Mark dimensions: Diameter or Side length 1mm~2mm,allowable offset 10%

Mark Shape: Cir,Rec, or rhombus etc

Mark Position: PCB dedicated mark or PCB pad

2D detection: Standard

- Accuracy

Table Adjustment Range: X=±3mm,Y=±7mm, θ=±1.5°

Positional Accuracy: ±0.01mm

Printing Accuracy: ±0.025mm

- Time

Cycle Time: <10s (ex print, cleaning time)

Convert line Time: <5min

Programming Time: <10min

- Control System

Computer Configuration: Industrial PC,Windows official system

System Language: Chinese、English

Pre and next machine :Connection SMEMA

User authorization: User PW and Senior PW set

- Cleaning System

Cleaning System: Dry and Wet (standard),vacuum model (option)

Liquid Level Detection: Liquid level auto alarm detection

- Power Parameters

Main Power Supply: AC 220V±10% 50/60HZ Single phase

Total Power: Approx.3kw

Main Air Supply: 4.5~6kgf/cm2

Machine Weight: Approx. 900Kg

Machine Dimension: 1140(L)x1380(W)x1530(H)mm (standard) /1675(L)mm (add loading unit)/1675(L)mm(add buffering unit/ 2210(L)mm (add loading and buffering unit)

- Option

Pneumatic Top Clamp: For thin PCB (thickness ≤1mm)

Top clamp + side clamp: For PCB (thickness ≤1mm)

Vacuum Adsorption and unloadding: For PCB (thickness ≤1mm) and FPC

Auto tin added: Auto tin added

Auto Loading and Unloading: /

Flexible and Universal Suppor: For the double-sided PCB(PCB backside parts Height ≤ 9mm)

Automatic Positioning of screen frame

PCB Thickness Auto Adjustment Function

Squeegee Pressure Feedback Function

Air conditioner: Customer can buy by themselves

The rest of Solder Paste on the stencil Monitoring System

SPI close loop

UPS power off protection: UPS 15min power off protection

Industry 4.0: Bar code trace function,production analysis etc

Catalog

- 良質な取り決め

- オリジナル保証

- 宅配便

- 買い取り簡単化