What is an automatic feeding machine? Reasons why automatic feeding machines enjoy this incentive

The automatic screw feeder is an essential equipment in the assembly industry, helping to increase efficiency and minimize errors in the production process. The machine's ergonomic and optimized design assists users in quick assembly, especially when large quantities of products are required. To achieve the highest efficiency, the operator needs to follow specific instructions and clearly understand the machine's features. This article will share how to customize an automatic screw feeder to achieve optimal accuracy. Please refer to it!

Contents

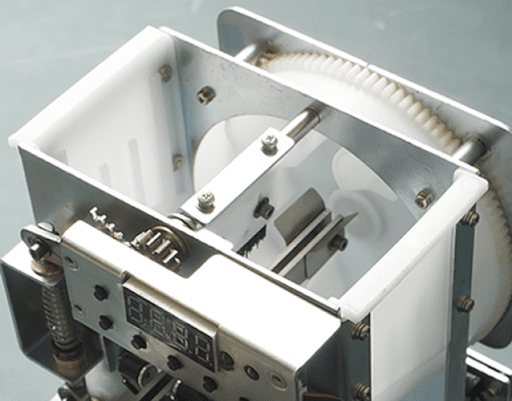

What is an automatic screw feeder?

To understand why automatic screw feeders are becoming popular equipment in production, it is first necessary to clearly understand its uses. Automatic screw feeders are widely used in electronic component assembly lines. This device is responsible for providing screws and screws during the assembly process of products such as electronic circuit boards, smartphones, computers, speakers, cameras, toys, and many other technology products.

In addition, the automatic screw feeder plays a role in quickly and accurately arranging screws in the right direction, helping to classify and supply suitable screws for each different type of screw head during the assembly process.

Screw feeders are very popular today, so what is the reason?

The popularity of automatic screw feeders today is no coincidence. This device stands out thanks to its many advantages and features, bringing countless benefits:

Save production costs:

This is one of the main reasons why automatic screw feeders are preferred in production. Compared to traditional manual or electric screwdrivers, automatic screw feeders significantly shorten screw delivery time, only taking about 1-2 seconds to complete one screw feed, 2-4 times faster than screwdrivers. with manual method.

In addition, using an automatic screw feeder helps reduce the need for manpower, as the device can completely replace manual screwdriving. Workers just need to bring the screwdriver head to the position to be assembled and press the button, ensuring the screw is installed in the correct position easily.

Ensure stable quality

The automatic screw feeder helps supply screws regularly and stably, ensuring high technical standards during the assembly process. The automatic system helps minimize errors and failures, providing consistent product quality.

Supports diverse screw classification and levels

With the automatic screw feeder, users can easily classify and supply many types of screws with diverse sizes, from M1.5, M1.7, M2.0, M2.3, M2.6, M3.0 , M3.5, M4.0, to M5 and lengths such as 1.4, 1.6, 1.8, 2.5, 2.8, 3.0, 3.5, 4.0, 5.0,... 10mm. The machine also supports many types of screws such as single screws, screws with flat washers, and warping pads, meeting diverse production needs.

Basic steps to operate an automatic screw feeder:

The first step is to check the power source and ventilation system, turn on the power switch and open the ventilation valve to ensure the device is ready to operate.

Next, check the travel of the transmission parts and pre-program coordinates for different products. Set screw paths and configure locking points accordingly. Then, place the product that needs to be screwed onto the machine, run step by step to check the accuracy of each position and journey.

Finally, conduct a test run of the machine to check the efficiency and quality of the finished product. After the system operates stably, it can be used continuously, but periodic quality checks and regular performance evaluation are needed to ensure optimal machine operation.

Applications of automatic screw feeder:

Automatic assembly in the electronics industry: Automatic screw feeders are widely used in the assembly process of electronic devices such as mobile phones, cameras, hard drives, keyboards, printers, computers, etc. DVD players, home appliances, plastic products, toys, electrical appliances, and communication devices. Using an automatic screw feeder saves time and reduces effort compared to manual screw tightening.

Automobile industry: Automatic screw feeders are also commonly used in automobile assembly, especially in the assembly of engines, motors, and other components. Wherever screws are needed, automatic screw feeders can replace manual operations, helping to reduce labor costs and increase production efficiency. This device allows for complete automation from moving the product, positioning, feeding and tightening screws. The operator only needs to put the product into the machine and periodically check the materials, which simplifies the process, ensures quality, and significantly improves working efficiency.