What role does a pipe threading machine play? Why should you use it?

Máy tiện ren ốnPipe threading machines are currently widely used in many areas of life, contributing significantly to improving productivity and efficiency in industries. The article below will help you better understand the machine and why you should use a pipe threading latheg hiện nay đang được ứng dụng rộng rãi trong nhiều lĩnh vực của đời sống, góp phần không nhỏ vào việc nâng cao năng suất và hiệu quả cho các ngành công nghiệp. Bài viết dưới đây sẽ giúp bạn hiểu rõ hơn về máy và vì sao nên sử dụng máy tiện ren ống

Contents

Concept of utility pipes

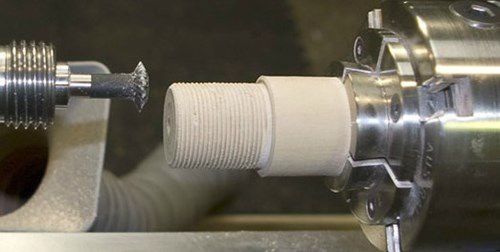

Pipe threading machine is used to support external threading on metal pipe ends such as steel, cast iron, copper, aluminum or HDPE plastic pipes. Operated by hand or electric motor, it helps workers easily create threads to connect pipes to each other or to accessories such as valves, adapters, connectors, connectors,...

The uniform spiral grooves of the pipe thread ensure a solid connection, helping the joints to be tightly sealed without worrying about leaks. The pipe threading machine is also capable of accurately processing pipes of many different sizes, meeting diverse needs in the mechanical industry.

Structure of pipe threading lathe

Electric motor:

The electric motor is the core part that helps the pipe threading lathe operate. Usually, the machine uses popular power sources such as 110V, 120V, 220V, etc. For high-end models, the power source requirements also increase accordingly. Therefore, before operating the machine, you should carefully check the engine parameters to ensure compatibility. The electrical switch is often located near the electrical wire to conveniently turn the engine on and off, helping users easily start and stop the engine when necessary.

Chuck:

The chuck is a part designed to hold metal pipes tightly during the threading process. They are mounted in pairs at both ends of the tube and are adjustable in size thanks to side screws. This makes it easy to change the distance between the clamps to accommodate different pipe sizes. With this flexible design, the chuck helps the threading process go smoothly, regardless of pipe size.

Machine mold:

The machine mold is responsible for creating threads on the ends of metal pipes. Equipped with sharp blades, the machine mold helps cut and create threads accurately and ensures high aesthetics for the cutting lines. Thanks to the optimal design, the machine mold helps the threading process take place quickly and achieve the highest accuracy.

Concentric shaft:

The concentric shaft of the pipe thread lathe is designed to resemble a drill bit, helping to fix the metal pipe during the turning process. Thanks to that, the pipe is held firmly in one position, helping the turning process to take place accurately, avoiding the pipe being misaligned, and ensuring the quality of the thread after completion.

C-shaped cutting machine:

The C-shaped cutter is a part used to cut off unnecessary metal pipe sections. When used, the worker will rotate the crank so that the blade gradually comes into contact with the pipe, then continue to rotate evenly until the unwanted part of the pipe is completely removed.

Classification of pipe thread lathe:

Classification of pipe thread lathes according to operating method:

Mechanical pipe threading machine:

This type of machine operates entirely based on mechanical manipulation. The user must perform steps such as clamping the pipe, adjusting the cutter, and turning the handle to create threads. This type of machine is suitable for simple jobs that do not require high speed or accuracy, and is suitable for small projects or that do not require large productivity.

Automatic pipe threading machine:

The automatic pipe threading machine is equipped with an automatic control system, helping to optimize the threading process. The worker only needs to set parameters such as thread size, rotation speed, and cutting depth, then the machine will automatically perform the entire process without much manual intervention. This type of machine has higher precision and performance, suitable for large mechanical workshops or mass production processes.

Classification of pipe threading lathes according to size and capacity:

Small pipe threading machine:

Small pipe threading machines are often used for small diameter pipes, such as in residential water supply and drainage systems. With a compact design and low power, this machine is easy to move and suitable for light work that does not require too high productivity.

Industrial pipe threading machine:

Industrial pipe threading machines are designed to process large diameter pipes, such as those used in the oil and gas industry or construction. This type of machine has large capacity and high load capacity, and is often permanently installed in large mechanical workshops to serve large-scale projects requiring high durability and performance.

Classified by power supply method:

Manual pipe threading machine:

Manual pipe threading machine uses the operator's labor, with manual rotation to create threads. This type of machine is suitable for simple manual work that does not require high precision and is often applied to small projects or basic repairs.

Electric pipe threading machine:

Electric pipe threading machines operate on an electric motor, providing high working efficiency and the ability to process a variety of pipe types in many industrial applications. This machine saves time and effort and is suitable for both small production and large industrial processes.

Why should you use a pipe threading lathe?

-The pipe threading machine ensures the creation of regular and accurate threads, helping the joints between pipes become tight and solid, minimizing the possibility of errors during installation.

- Compared to the manual threading method, the pipe threading machine helps speed up the process, reduce workers' labor and improve productivity, especially when large projects need to be carried out.

- Machine-made threaded connections often have high precision, thereby minimizing the risk of leaks or damage

- The pipe threading machine has the ability to flexibly adjust to fit many types of pipes of different sizes, from small pipes to large pipes, meeting diverse needs in many industries.

- Pipe threading machines are commonly used in fields such as water supply and drainage, oil and gas, construction, and air conditioning system installation,... helping to connect pipe systems effectively and efficiently. safe.

Reference:

Pipe threading machine SMAC Z1T-B3-80

Lushun Z1T-R2 pipe threading lathe

Conclude:

So if you are in need of using a pipe threading lathe, do not hesitate to contact us to receive detailed advice and the most accurate quote. EMIN provides a variety of pipe threading machines with rich designs, guaranteed quality and written commitment. We also support repair services after the warranty period, giving customers peace of mind and satisfaction when using the product.