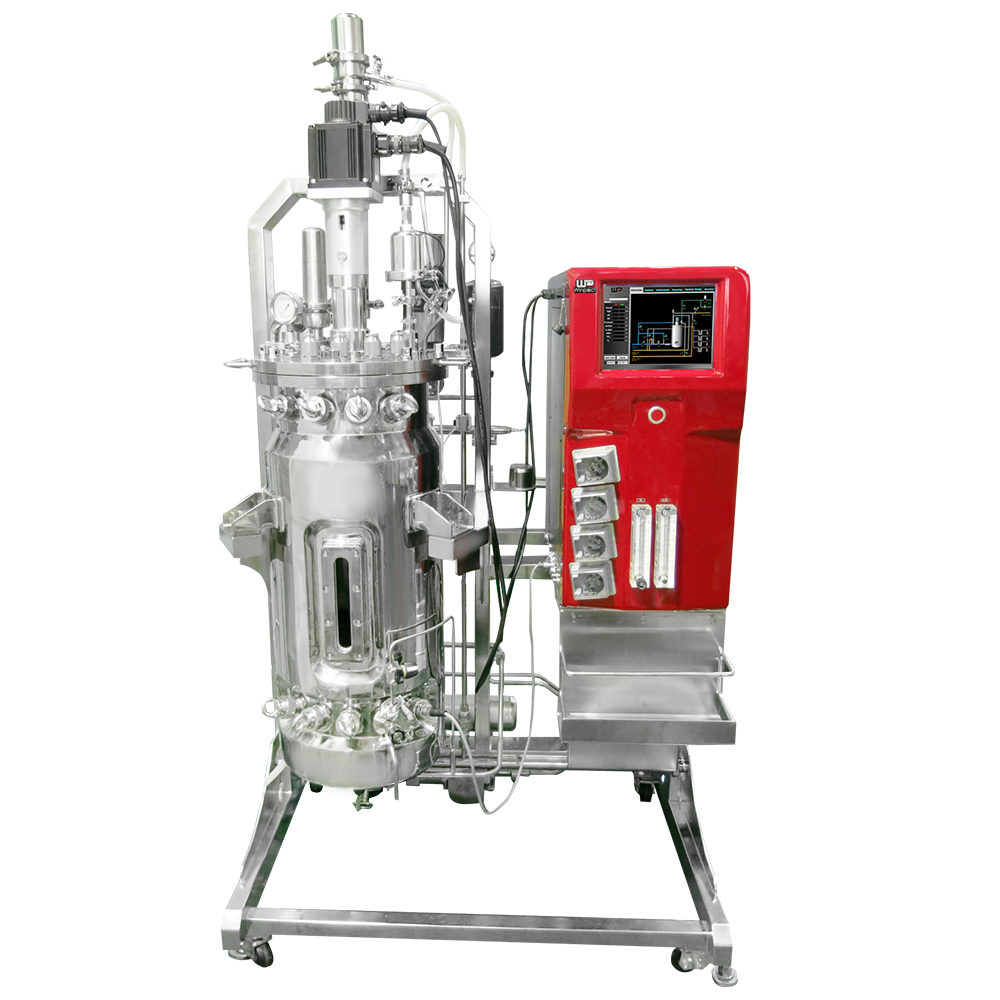

Major Science FS-50L SIP Fermentation System (50L, 130 x 95 x 295 cm)

制造商: Major Science Model: FS-50L - 联系

Capacity: 50 L

Total volume: 67 L

Working volume: 50 L

Dimension: 130 x 95 x 295 cm

Vessel and jacket maximum working pressure: 3 bar (43.5 psig) / 4 bar (58 psig)

Type: Double layered fully enclosed capsule-type tank

Material: Direct contact to medium - 316L stainless steel; all others - 304 stainless steel

Surface finish: Interior polish ≦ 25 Ra/in (0.6 μm) Mechanical polishing; Electropolish optional

Exterior polish ≦ 32 Ra/in (0.8 μm) Mechanical polishing; Electropolish optional

Ports:

Ports designed according to user requirements

Piping and valve materials:

Parts that directly contact with the product/medium uses 316L stainless steel (≤25 Ra/in) internal polished tubing (BPE standard) :

A. Internal EP polished diaphragm type pneumatic valve and manual valve (BPE standard)

B. Tubing all welded with orbital welding

C. Vessel bottom drain uses a diaphragm valve, to minimize dead volume

D. Piping designed for ease of transfer to scale up (can be used as a seed fermentation system) or downstream process

Parts that do not directly contact product/medium

A. Constructed with 304 stainless steel

Controller: 10.4” color industrial touch screen

Setting

* Automated sterilization process

* Automated fermentation program

DO

* 0-200%, Control range:0-100%, adjustable

* Software electrode calibration, with automatic temperature compensation function

* Includes one set of side-inserted stainless steel autoclavable DO electrode

* DO Stat features with intelligent feeding

pH

* PID control with adjustable deadband

* Control range0 to 14 (2-12 for maximum precision), resolution: 0.01 pH

* Calibration function with automatic temperature compensation function

* Includes one set of side-inserted, autoclavable pH probe with stainless steel housing

* pH Stat features with intelligent feeding

Pump

* Built-in peristaltic pumps

* Each feeding pump can run adjustable 15-step program

* Each pump can be adjusted for speed, forward and backward direction, and manual or automatic mode

* Each of the four peristaltic pumps can be designated for different functions: acid pump, base pump, antifoam pump, or substrate feeding pump

* Optional fifth and six peristaltic pump available

Temperature

* Vessel temperature is measured with a side-inserted PT-100 temperature probe and maintained using PID control.

* Control range: 0-130°C, ±0.1°C. Operational range up to 0-60°C

Agitation

* Manual or automatic control of agitation speed

* 15-step program to change speed, or use DO cascade control

Air supply and exhaust Gas supply and dehumidifer: uses in-house air compressor or air dehumidifier

* Includes re-useable, autoclavable 0.2μm air filter for gas inlet

* Gas Inlet (air)

Includes mass flow controller:

2 vvm maximum according to the vessel capacity

* Gas Inlet (oxygen)

Includes pure oxygen rotameter (manual flow control):

1 vvm maximum according to the vessel capacity

* Includes oxygen gas solenoid valve, with automatic pulsed time control

Air outlet / Exhaust

* Exhaust port with stainless steel condenser

* Includes re-useable, autoclavable 0.2μm air filter

* Includes automated adjustable gas outlet valve to adjust vessel back pressure

* Can control manually or automatically via software

Utility Requirement

Capacity: 50L

Power: Three phase 220V or 380V (note: can be customized to local standard)

Air:

At least 6 bar

100 L/min flow rate

Dehumidified

Oil-free

Peripheral factory water supply: Cooling water (tap water, at least 15 °C below working temperature, must be soft water) ;

Pressure at least 2 bar

Process water: RO Water

Plant steam: ≥ 2 bar; dry steam with no entrained condensate

Process steam: ≥ 2 bar; dry steam with no entrained condensate

Drain: In situ drain; ≥ 1"

*Customization on the SIP Fermentation system available upon request.

The 30L SIP Pilot Scale Fermentation Systems allows you to run small volume of fermentation experiments with ease. These systems are perfectly suitable for small scaling-up in the academic lab. The easy programming and operation on our Winpact software makes your operation procedure in your peace of mind. This fermenter comes with rolling wheels for mobility. All materials are made from the highest standard to ensure optimization of your fermentation process. A variety of optional devices are also available to maintain your optimum performance.

B1.Motor - Manual or automatic control of constant agitation speed.

B2.Stainless Steel - Vessel Special designed heating jacket provides better heating efficiency

B3.Peristaltic Pump - Uses four Watson Marlow built-in peristaltic pumps for all your feeding needs

B4.Control Station - Large screen and graphical user interface

Catalogue

Brochure

Video

- 质量承诺

- 正品保修

- 送货到家

- 交易简单化