What is hydraulics? Common applications of hydraulics

During machine maintenance, disassembling and assembling bearings is always a time-consuming process, especially when the bearings are stuck or corroded. To deal with this problem, many technicians use hydraulic pullers to support the disassembly process more easily. So how does a hydraulic puller work? What is its structure? Let's find out more with EMIN.

Contents

What is a hydraulic puller?

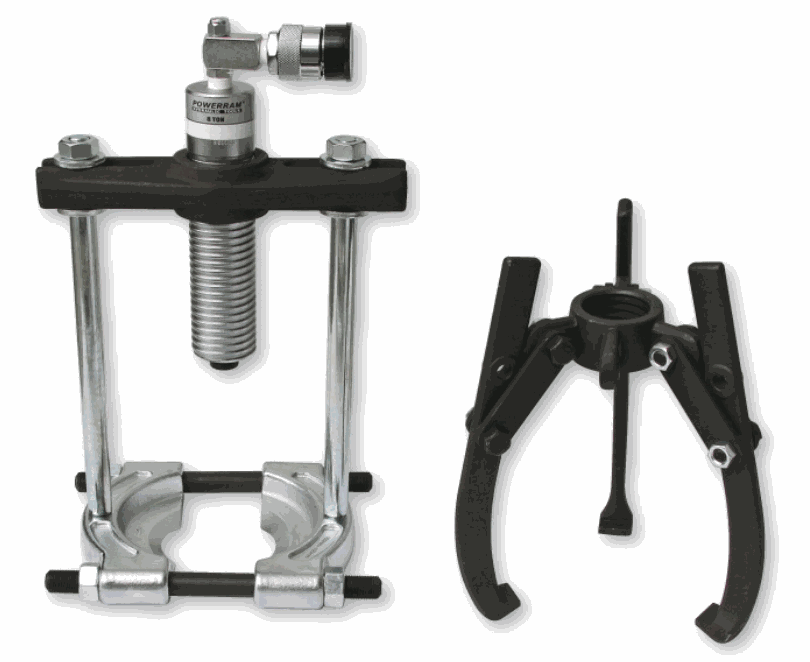

For those who do not know, hydraulic pullers are used to remove and install bearings on machines and cars. This tool is commonly used in industrial and civil equipment lines, supporting the assembly and maintenance process more conveniently.

Hydraulic puller classification

After understanding the uses of hydraulic pullers, classification will help choose the right equipment. Currently, hydraulic pullers are divided based on two factors: the source of impact force and the number of jaws.

Classification by impact resources

There are three main types based on the way the pulling/opening force is created:

Hydraulic pullers use compressed air.

Hydraulic pullers have a hydraulic system integrated right on the machine body.

Hydraulic pullers use a separate hydraulic system, operated by a hand pump or an electric pump.

Classification by number of spokes

Based on the clamp jaw design, there are two common types:

2-jaw hydraulic puller.

3-jaw hydraulic puller.

Currently, many lines of pullers can flexibly switch between 2-jaw and 3-jaw modes, helping users easily adjust according to work requirements.

In addition, hydraulic pullers are also classified according to maximum pulling force (5 tons, 10 tons, 15 tons, 20 tons ... 50 tons) or leg opening range, helping to choose the right equipment for each specific application.

Structure and working principle of hydraulic pullers

Hydraulic pullers are designed with a hydraulic system to optimize the process of removing and installing bearings. Thanks to this mechanism, machine maintenance becomes faster and more convenient. So what is the structure and operating principle of hydraulic pullers?

Structure

The design of the hydraulic puller is quite simple, consisting of three main parts:

Central shaft: Is the part that directly contacts the center of the bearing or rotating shaft, playing the role of fixing the position when operating.

Puller jaws (feet): Have the task of gripping the outer edge of the bearing to perform the removal or installation process. Depending on the design, the puller can have 2 or 3 jaws.

Pump body (or separate pump): Provides pulling force through the hydraulic or pneumatic system, helping to create enough force to remove or install the bearing easily.

Principle of operation

When used, the operator will apply pressure to the hydraulic or pneumatic system, thereby activating the cylinder to push the piston up. This force is transmitted to the center shaft and the jaws of the puller to directly impact the bearing.

When removing the bearing: The center shaft is fixed to the machine shaft, while the jaws pull the bearing out of its original position.

When installing the bearing: The jaws will receive pressure, pushing the bearing into the correct position on the shaft until it is completely engaged.

Thanks to this principle, the hydraulic puller makes removing and installing the bearing easy, avoiding damage to components and saving time compared to manual methods.

Notes when choosing to buy hydraulic pullers

Choosing the right hydraulic puller makes the job of removing and installing bearings easier and also ensures the longevity of the equipment. Here are some important factors to consider when choosing to buy a hydraulic puller:

Determine the usage needs: First, you need to consider the type of bearing or machine part that needs to be removed and installed to choose a puller with the appropriate diameter and opening force. At the same time, you need to measure the distance from the shaft end to the inner edge of the part to ensure the puller is the right size.

Consider the price: Each type of hydraulic puller has a different design and features, so the price will also vary. Determining your budget before buying will help you easily choose the right product while still ensuring effective use.